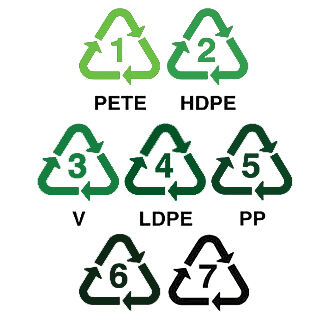

We support the customization of environmentally friendly materials to replace non-degradable plastics.

This material can be degraded by microorganisms in the natural environment, reducing environmental pollution.

This is a biodegradable polymer extracted from corn and other plant starches after fermentation. It is non-toxic and harmless to the environment and can be degraded in the natural environment.

These two materials use environmentally friendly catalysts and additives during the production process, which have less impact on the environment and have good degradability.

As a recycled material, RPET has good processability and recyclability. It can be recycled multiple times during use, reducing the consumption of original petroleum resources and reducing environmental pollution.

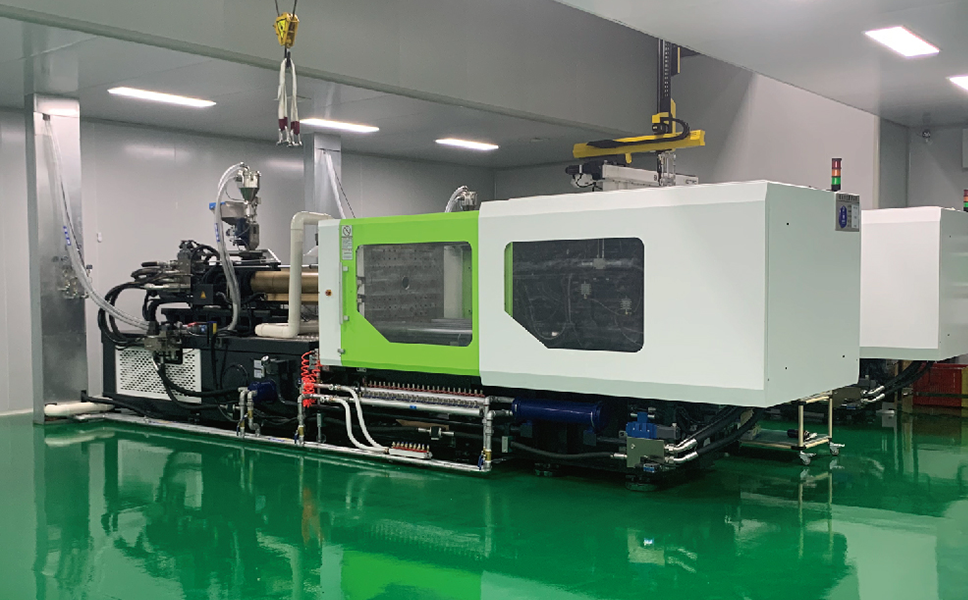

Intlpack clean workshop is produced in the same workshop as medical packaging, making it truly sterile. Starting from the needs of dairy & beverage manufacturers, we provide one-stop services from product design and development to production, packaging, quality inspection and customs to meet customers' product and service needs.

Intlpack provides cups, lunch boxes, cutlery, spoons, tableware and other environmentally friendly material products for fast food restaurants and milk tea shops. We provide one-stop services from product design and R&D to production, packaging, quality inspection and customs clearance to meet customers' product innovation needs

Intlpack strictly implements relevant laws and regulations and industry standards, selects environmentally friendly materials, reduces the harm to the environment from the source, and promotes the healthy development of the injection molding industry.

Read More

Intlpack adopts optimization measures when using injection molding machines, adjusting the stability of the operation of the injection molding machine, controlling the injection cycle, etc., so as to improve the efficiency of the injection molding machine as well as energy saving and emission reduction.

Read More

Intlpack adopts recycling, re-processing and production recovery methods when dealing with injection molds and plastic wastes to minimize the generation of unreasonable wastes and pollution to the environment.

Read More

Intlpack strictly follows the national laws, regulations and standard specifications on environmental protection to minimize the generation of wastewater, exhaust gas and hazardous waste in the production process to ensure the sustainable development of the company.

Read MoreWhether you want to order directly, or customize a private product, we are here to help. Ready to take your business to the next level? Contact us today and let’s create something amazing together.